MATERIALS

LIME PUTTY

We have always selected our raw materials with the utmost care, since they constitute the substance which can give shape to the wishes of our most demanding clients.Lime putty is our element of choice. Lime is a high quality material in and of itself: it originates from carefully selected quarry stone, which is slowly cooked at about 950-980 °C.This produces quick lime, which is then extinguished with water to obtain quick-setting lime putty. At this point the material is aged in dedicated tanks for at least for 6-8 months and up to 10 years or more. During this time, a physical change takes place: hexagonal putty crystals gradually and slowly set in parallel rows, which look like sausages, making the material viscous, firm and workable, ready to be used.

The main features of lime putty can be summarised as follows: natural, healthy, breathable, resistant to temperature changes, durable and consistently workable. We carefully select lime putty which is manufactured with traditional methods, respecting the appropriate processing stages and the required times, so as to consistently yield the highest possible quality.

EARTH COLOURS

They should be extremely pure as to provide for a lasting colour when in contact with the hot irons used during polishing. In this way, the colours and shades obtained with hot stucco are extremely bright, transparent and deep.

MARBLE POWDERS

Marble powders are selected according to their granulometry and their natural colouring, based on the desired end results of the finish.

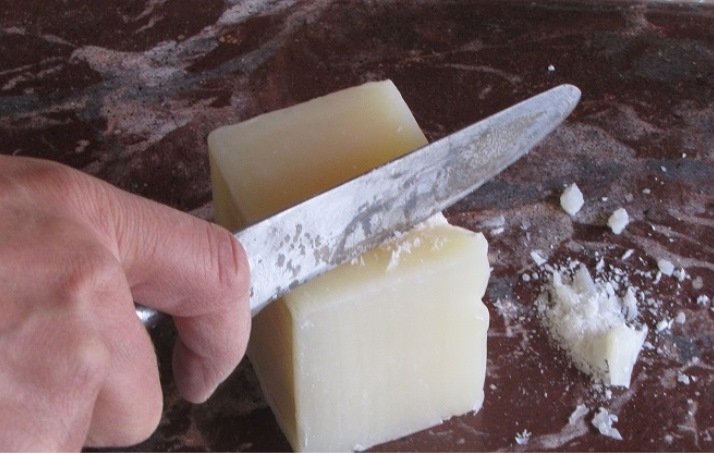

MARSEILLE SOAP

We process Marseille soap to use it in the final stages of our hot-iron stucco finishes. Once more, the initial differences between the different qualities of soaps lead to consistently different final results, and as such they are a major variable to consider when aiming for the best possible outcome.